FAQ > Mobile Onsite Service Windshield, Door, Vent, Quarter and Rear Back Window Glass Replacement Questions

•

How long will it take to replace my windshield or other auto glass?

What

we

would

call

a

normal

mobile

auto

glass

installation

usually

takes

from

45

to

90

minutes.

Installations

that

take

longer

than

90

minutes

are

what

we

classify

as

difficult

installations.

For

obvious

reasons

it

is

not

practical

for

us

to

do

these

types

of

installations

in

the

field

so

they

do

not

qualify

for

our

mobile

On

site

service.

As

a

rule

they

require

that

the

installation

be

performed

and

monitored

for

a

period

of

time

in

our

facility.

Some

of

these

types

of

installations

are

timely

because

they

are

done

in

stages,

some

of

which

cannot be accomplished until the adhesive has cured for a minimal amount of time.

Most

vertical

set

windows

such

as

a

pickup

truck

back

glass

may

require

being

held

in

place

by

different

manners

and

for

many

reasons

(paint

damage

being

the

main

one)

need

to

be

done

in

and

remain

in

our

service

centers

controlled environment until the adhesive cures for a certain amount of time.

•

Will you vacuum up the broken glass?

Absolutely!

Don't

touch

that

mess

and

risk

getting

hurt.

We'll

do

our

very

best

to

vacuum

up

the

broken

glass

to

make

your

vehicle

the

best we possibly can.

•

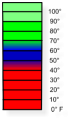

Is it ok to have my windshield installed in cold weather?

The

answer

to

your

question

varies

greatly

depending

on

the

vehicle

in

question

but

cold

weather

is

a

definite

game

changer

for

the

majority

of

today’s

vehicles

as

they

contain

several

plastic

components

such

as

cowls,

moldings

and

fasteners

that

become

extremely

delicate and difficult to work with below 50F (10C).

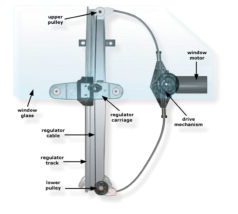

•

If

the

vehicle

has

a

cable

type

manual

or

power

window

regulator

the

only

sure

way

to

remove

all

the

broken

tempered

glass

fragments

is

with

compressed

air.

These

types

of

door,

quarter,

or

back

glass

window

regulators

have

several

places

that

the

tiny

pieces

of

broken

tempered

glass

can

fall

into

as

well

as

grease

points

that

lubricate

the

moving

parts.

When

the

glass

is

broken

the

falling

broken

tempered

glass

fragments

will

adhere

to

these

grease

points

like

a

magnet

and

it

only

takes

one

tiny

piece

of

glass

to

get

caught

and

jam

up

the

mechanism

causing

the

window

regulator

to

break.

We

have

seen

some

of

these

cable

door

glass

regulator

units

cost

as

much

as

$600

dollars

to

replace

so

taking

an

unnecessary

chance

with

these

fragile

cable

type

window

regulators

just isn’t a good way to go.

•

Some

hatch

type

back

glass

installations

such

as

the

GM

vehicle

pictured

to

your

right

have

an

inner

skeleton

that

fills

with

broken

tempered

glass

fragments

and

absolutely

cannot

be

removed

without

the

use of compressed air.

•

Some

doors

do

not

have

large

enough

access

holes

to

the

interior

area

of

the

door

that

will

allow

a

vacuum

hose

to

pass

through

the

entire

range

of

the

door.

In

many

cases

the

only

access

is

through

the

speaker

opening

and

the

only

method

of

removing

all

the

broken

tempered

glass

is

with

the

use

of

compressed air.

•

When

the

door

or

rear

window

back

glass

breaks

the

tempered

glass

fragments

inside

the

door

fall

and

are

captured

within

the

rails

of

the

vehicle's

inner

guard

beam

and

can

not

be

accessed

directly

by

the

vacuum and absolutely cannot be removed without the use of compressed air.

Due to the construction of some vehicles,

the door, quarter and back glass replacement windows need to and should be done in at our service center.

Here are just a few examples:

•

After I have my windshield replaced, how do I know if it was done right?

You

don't!

Without

removing

the

windshield,

it's

impossible

to

tell

if

the

windshield

was

prepped

correctly,

if

critical

primers

and

proper

flash

times

were

used,

or

even

if

the

proper

amount

and

type

of

urethane

was

used.

Once

a

windshield

is

installed

all

the

critical

installation

preparation

steps

are

hidden

under

the

moldings

and

black

ceramic

band.

If

it

looks

like

a

clean

windshield,

back

glass

or

other

type

of

auto

glass

installation

and

the

moldings

are

lying

correctly

you

can

only

guess

it

was

done

right

and

in

reality

those

things

are

only

cosmetic,

it's

what

is

underneath

and

when

and

how

it

was

done

during

the

replacement

installation

process

that

counts.

The

only

sure

way

to

tell

if

a

windshield

or

other

type

of

auto

glass

is

properly

installed

is

to

crash

test

it,

but

we

sure

don't recommend it.

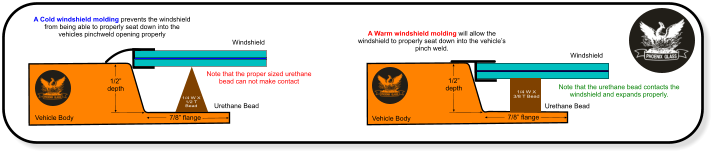

Another

major

problem

would

be

a

windshield

glass

with

an

encapsulated

molding,

or

just

about

any

molding

that

is

attached

to

the

windshield

for

that

matter,

installed

in

cold

weather

is

that

it

would

“most

likely”

not

be

able

to

seat

down

properly

into

the

vehicles

pinchweld

which

would

elevate

the

glass

high

above

it’s

intended

position

resulting

in

a

poor

bond

(likely

a

leak)

and

at

the

very

least

cosmetic

problems.

The

typical

auto

glass

installers

solution

in

that

situation

is

to

combat

it

by

applying

an

oversized

bead

of

urethane

to

insure

that

it

makes

full

contact

which

in

turn

opens

the

installation

up

for

several

other

problems

such

as

the

molding

not

laying

flat

as

well

as

being

able

to

slip

off

the

windshield.

Another

reason

this

should

never

be

done

is

that

a

much

larger

bead

of

urethane

will

require

a

significantly

longer amount of time for the urethane adhesive to cure which will have a major affect on the occupants safety.

Some

windshield

companies

or

installers

may

tell

you

that

they

use

a

fast

cure

urethane

that

has

a

one

hour

drive

away

time.

In

our

real

world

experience

the

one

hour

drive

away

time

is

only

true

when

the

adhesive

is

applied

as

the

manufacturer

intended

it

to

be.

All

the

figures

stated

by

the

manufacturers

of

urethane

adhesive

products

are

typically

based

on

a

6mm

x

12mm

bead

or

a

1/4

by

1/2

inch

bead.

The

larger

the

bead

of

adhesive

is,

the

longer

the

curing

time

will

be

unless

there

is

a

2

part

chemically

induced

curing

urethane

adhesive used which is very seldom, if ever, used in the mobile on site auto glass windshield replacement industry.

Another

sales

pitch

myth

that

goes

around

in

the

wild

world

of

windshield

and

auto

glass

replacement

is

that

an

installer

can

use

a

heat

box

to

maintain

the

urethane

adhesive

used

for

cold

weather

installations

at

the

proper

temperature

so

installing

your

windshield

in

cold

weather

won’t

be

an

issue.

The

Urethane

adhesive

used

in

the

automotive

industry

to

bond

your

windshield

and

other

auto

glass

installations

like

door

glass

side

windows,

quarter

glass

windows

and

rear

back

glass

windows

to

your

vehicle

is

an

extremely

thick

material

in

its

uncured

state.

The

real

truth

and

reason

for

the

heat

box

is

to

keep

the

urethane

at

a

temperature

that

makes

the

urethane

adhesive

what

is

referred

to

as

gun-able

which

simply

means

thinner

thus

more

usable.

What

that

means

in

the

real

world

is

that

by

keeping

the

adhesive

warm

it

can

be

easily

pumped

from

a

hand

or

power

caulking

gun

with

a

lot

less

effort.

It

does

without

a

doubt

make

the

urethane

adhesive

much

easier

to

apply

but

by

the

time

you

finish

applying

it

on

the

vehicles

cold

steel

metal

pinchweld

opening

“on

average

some

fourteen

or

more

feet

in

circumference”

and

try

to

place

the

cold

windshield

in

position,

the

urethane

will

be

at

ambient

temperature

making

the

windshield

extremely

difficult

to

press

down

into

the

proper

depth

defeating

the

whole

purpose.

At

the

critical

moment

when

the

windshield,

back

glass

or

other

type

of

auto

glass

is

set

into

place

it

requires

warm

adhesive,

a

warm

molding

typically

at

or

better

then

70

degrees.

With

cold

metal,

adhesive,

windshield

and

a

cold

molding,

to

top

it

all

off

it

really

isn’t

likely

it’s

going

to

be

what’s

referred

to

as

a

good

set

or

installation.

Also

typically

the

complete

operation

from

the

first

inch

of

the

application

of

the

urethane

adhesive

must

be

accomplished

within

an

8

to

10

minute

time

frame

before

the

urethane

begins

to

skin

over

or

harden

and

thats

with

a

preprepared

windshield

or

other

type

of

glass

that

was

previously

primed

at

or

above

40

degrees

and

stored

in

a

way

that

it

would

keep

it

free

from

any

and

all

contamination

hazards

on

the

bonding surface of the glass.

The

next

best

way

to

know

is

to

know

the

reputation

of

the

company

that

installed

it.

Make

sure

the

company

has

an

actual

address

complete

with

an

actual

store

front

as

there

are

many

gypsy

type

auto

glass

companies

operating

in

and

around

Knoxville

as

well

as

it’s

surrounding

areas.

No

store

front

usually

goes

hand

in

hand

with

a

pick

up

truck

and

a

cell

phone.

You

can

easily

accomplish

this

using

Google

Maps

Street

View

.

Google

allows

you

to

see

if

the

company

your

considering

using

for

the

installation

of

your

new

replacement

windshield

turns

out

to

be

a

home,

an

apartment

complex

or

even

an

empty

lot.

With

the

power

of

the

internet

anyone

can

make

a

attractive

website

to

lure

you

in.

They

typically

have

no

liability

insurance

and

when

something

goes

wrong

you

are

on

your

own

since

they

are

very

difficult

to

track

down

and

with

the

power

of

Caller

ID

they

stop

answering

your

repeated

phone

calls.

Due

to

poor

workmanship

during

the

average

month

here

at

Phoenix

Glass

we

re-do

auto

glass

in

about

6

vehicles

per

month

from

this

type

of

so

called

auto

glass

company.

By

the

time

you

add

up

the

expenses

of

a

new

glass,

mouldings

and

repairing

the

body

damage

that

was

done

to

the

pinchweld

the

price

for

repairing

a

vehicle

in

this

type

of

situation

is

usually

3

to

4

times

what

it

would

have

cost

if

it

were

done

right

in

the

first

place.

Unfortunately

most

of

these

installers

are

or

were

employed

and

trained

by

some

of

the

major

chain

outfits

where

they

learned

these

corner

cutting

traits

to

make

more

money

and

actually

have

convinced

their

selves

to

believe

that

they

are

doing

the

work

properly.

Typically

these

employees

are

paid

by

salary

plus

commission.

In

slow

times

the

employee

gets

the

minimum

pay

to

save

the

company

money

but

when

times

are

busy

as

an

added

incentive

the

employee

is

given

a

commission

based

on

production.

The

more

jobs

completed

the

more

pay

received

and

the

only

way

that

can

happen

is

by

speeding

up

the

installation

process

which

is

where

something

has

to

suffer

in

order

to

make

that

happen

and

it’s

usually

you

and

your

vehicle.

In

the

event

these

short

cuts

lead

to

a

problem

at

the

very

least

your

going

to

loose

some

valuable

time

having

your

vehicle

redone

and

at

the

very

worst

it

can

lead

to

serious

injury

or

the

loss

of

your

life

or

that

of

someone

you

love

so

be

very

careful

when choosing who you let install your windshield or other glass in your vehicle.

With

all

the

different

variables

of

windshields,

side

door,

quarter

and

rear

back

glass

windows

and

other

types

of

auto

glass

parts

that

are

involved

in

the

many

makes

and

models

of

cars,

trucks

and

SUV’s,

fifty

degrees

“in

our

experience”

is

pushing

it

all

toward

the

red

line

about

as

far

as

one

can

go

with

out

having

any

drama

or

incidences

such

as

parts

breaking,

cracking

or

seating

properly

and

get

anywhere

close

to

a

good

windshield

or

any

other

type

of

auto

glass

installation

if

you

take

everything

thing

thats

involved

into

consideration.

All

thats

left

to

add

to

the

equation

is

the

picture

of

the

cold

installer

with

the

frozen

fingers

and

it

pretty

much ends up with the word Fail in the end.

Most

door

glasses

that

operate

in

an

up

and

down

manner

average

45

to

90

minutes

to

install

and

in

most

instances

you

will

be

able

to

operate

them

immediately.

In

the

event

that

there

is

a

urethane

bonding

system

involved

you

may

not

be

able too operate your new window until the adhesive cures after a minimum of 24 hours.

•

Can Phoenix Glass set an appointment time for my mobile on site windshield replacement?

We

would

really

like

to

be

able

to

do

that

for

you

but

the

best

we

can

honestly

do

is

a

four

hour

window.

Almost

every

auto

glass

company

gives

you

a

4

hour

window

of

the

time

that

they

will

arrive

at

your

location.

If

they

don't

it's

because

you

are

the

only

one

they

are

working

for

that

day

which

should

light

a

pretty

bright

light

bulb

in

your

mind.

In

reality

a

4

hour

window

is

about

as

precise

as

scheduling

gets

for

an

honest

auto

glass

windshield

replacement

company

that

offers

mobile

auto

glass

service.

Mobile

auto

glass

replacement

is

a

service

industry

trade

where

a

technician

often

encounters

unexpected

situations

not

only

with

the

vehicle

involved

but

traffic

and

weather

related

items

as

well.

Some

jobs

are

easy

and

some

are

very

difficult.

Some

customers

are

easy

and

some

have

lots

of

questions.

Some

insurance

companies

we

do

work

for

have

extensive

before

and

after

on

site

paperwork

involved

which

can

add

quite

a

bit

more

time

to

a

particular

job.

At

least

once,

if

not

more,

on

a

busy

mobile

auto

glass

technicians

day

a

customer

will

cancel

or

not

be

there

or

may

not

answer

their

phone

to

verify

that

they

are

there.

Many

times

while

on

site

at

a

body

shop

our

auto

glass

technicians

will

have

an

unplanned

job

added

or

postponed

because

it

isn’t

ready

to

be

installed

which

changes

the

entire

daily

job

plan.

Please

keep

in

mind

that

we

aren't

trying

to

make

excuses

here,

we're

just

being

honest

and

pointing

out

some

of

the

pitfalls

of

our

average

day

so

you

can

have

an

understanding

of

some

of

the

reasons

why

we

can't

give

you

an

honest

appointment

time.

The

reasons

go

on

and

on

but

the

bottom

line

here

is

that

the

technician

will do his or her very best but some things are just not in their control.

If conditions are too cold for your particular vehicle at the available installation time for

a safe and or sensible installation we will suggest that your replacement glass

installation be done in our service centers climate controlled environment.

Our Customer Service Representatives will do their best to advise you

whether or not your vehicle can or should be done mobile.

•

How do I know your installers are qualified?

Your

Phoenix

Glass

Auto

Glass

Technician

keeps

up

with

the

times

and

have

a

high

degree

of

understanding

of

the

ins

and

outs

of

rear

back

glass

window

replacements.

They

are

familiar

with

the

proper

tools,

methods

of

removal,

preparation

of

the

pinchweld

and

possess

the

knowledge

of

the

many

different

adhesives

available

that

will

provide

the

strength

to

hold

the

back

glass

in

your

vehicle.

Along

with

all

that

they

also

understand

and

use

the

proper

methods

that

prevent

leakage

and

rust

around

the

pinchweld

where

the

auto glass bonds to the vehicle.

Phoenix

Glass

technicians

have

as

much

as

42

and

none

less

than

15

years

of

auto

glass

experience

and

have

literally

installed

thousands

of

rear

window

back

glass

windshields.

You

can

rest

assured

that

your

new

replacement

back

glass

will

be

properly

installed

to meet both

FMVSS

and AGRSS standards so that your vehicle will be restored to the factory specifications or better.

There are many different types of vehicles in today’s world and each of them have their own peculiarities.

Your customer service representative at Phoenix Glass will be more than happy to answer any questions you may have for your

particular vehicle.

This is a Chevrolet Monte Carlo that had a previous windshield installation done in cold weather

taken from 1 of our poor workmanship pages.

You

can

plainly

see

that

the

flange

of

the

windshield

molding

held

the

windshield

from

being

allowed

to

sink

down

to

the

correct

hight

within

the

vehicles

pinchweld

flange

causing

the

windshield

to

sit

extremely

elevated

above

the

vehicles

body.

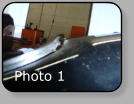

The

thick

lines

at

the

top

of

the

moldings

in

photos

1

and

2

are

the

cut

off

top

flange

edge

of

the

molding

that

lap

over

the

cars

body.

We

cut

them

off

to

show

exactly

where

it

is

in

elevation

above

the

car

body.

The

molding

should

be

sitting

down

just

barely

above

the

level

of

the

body

the

thickness

of

the

top

flange

edge

of

molding.

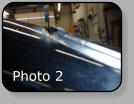

In

photo

3

you

can

actually

see

the

massively

tall

bead

of

urethane

adhesive

that

was

applied

to

compensate

for

the

situation.

The

Monte

Carlo

is

one

the

most

popular

vehicles

in

America

at

the

time

of

this

writing

and

the

windshield

molding

on

this

car

and

many

makes

and

models

of

vehicles

just

like

it

are

very

rigid

when

they

are

cold.

They

should

never

be

done

in

cold

weather

because

without

an

extremely

warm

windshield,

molding,

adhesive

and

vehicle

the

windshield

absolutely

will

not seat properly.

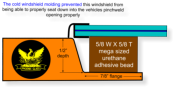

A real world example of what happens in this type of cold weather windshield installation:

Copyright 2013 © Phoenix Glass, Inc. All Rights Reserved

Revised June 2023

Please Like Us

on Facebook